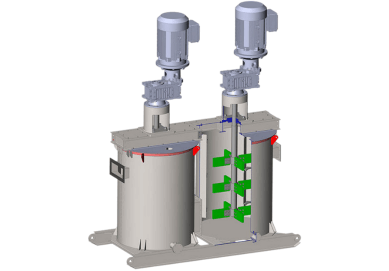

UPC offers attrition machines with an optimised impeller design to ensure your plant runs efficiently. We use the latest mixing technology in our designs while many other attrition machines are still utilising designs from the 1970’s.

TYPICAL APPLICATIONS:

- Mineral Surface Cleaning

- Clay Removal

- Iron Oxide Removal

- Flotation Conditioning

FEATURES:

- Multiple Shear Zones

- High Efficiency Impeller Design

- Wear Resistant Material Options

- Modular Construction

- Easy Upgrade of Existing Machines